The Big Bean Bag Company

/The Big Bean Bag company was launched in 2018 by David & Lucy. Based in Cornwall, they have created the world’s first truly eco-friendly beanbag. I discovered the company last year and having used them in a recent project I was interested in finding out more about the business, their focus on sustainability and how they got to where they are today.

What was your vision when you started The Big Bean Bag Company?

We wanted to create a company which puts sustainability at the forefront of business decisions. We wanted to ensure we used the highest quality components and were as eco friendly as possible in our efforts. We also wanted to offer employment opportunities for our local area in Cornwall.

Where did you get the idea for the company?

We had some old beanbags in the house and we wanted to give them a new lease of life. When we went to order the polystyrene balls refills we realised that there wasn’t a sustainable option on the market and so we decided to research a way to create a product that was more sustainable, not just in terms of the filling but also the rest of the product.

What makes your bean bags truly green?

Unlike most other bean bag companies, our bean bags aren’t filled with harmful styrofoam beads. Most of these plastics end up in landfill or the ocean, taking hundreds of years to break down. Styrofoam ends up floating on the water and being ingested by wildlife.

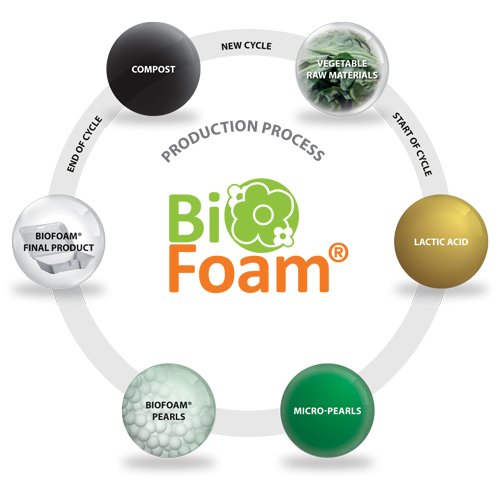

We use a compostable filling, not used by any other bean bag companies across the world. They are filled with BioFoam® beads, a compostable biopolymer made from plants, that is child and pet friendly, doesn’t harm the environment and keeps its shape, ensuring our bean bags are incredibly comfortable.

Not only this but are products are sewn with thread made from recycled plastic bottles, our fabrics are sustainably sourced and our warehouse uses 100% recycled energy making our beans the first truly eco friendly bean bag in the world.

We also want our beanbags to be for life so we offer our filling as a refill in, which you can easily top up yourself at home. If you’ve damaged the exterior fabric of your product, you can send it back and we can repurpose the material in cloths and wipes and supply you with a new outer cover at a discounted price. Our filling can also be recycled by using a hotbed or can be industrially composted.

How long did it take to create your bean bags and what challenges did you face?

The first challenge was finding environmentally friendly, polystyrene substitute that wouldn’t degrade or crumble, or impact on the comfort of their beanbags. Enter, the University of Plymouth’s Acceleration Through Innovation (ATI) programme, who through their research discovered the ‘magic beans’. Plant-based, fully compostable, CO2 neutral, non-toxic, and durable yet still comfortable, BioFoam was just the filling we had been dreaming of.

Lucy designed the initial range over 9 months and we had intended not to manufacture our products in house. However, we quickly realised that we had to go down that road to ensure the quality of our products never drop and to ensure we can keep up with demand.

Where do you see The Big Bean Bag Company in 5 years time?

We are opening an office in Detroit, USA in April as we start to offer our products to different parts of the world. We also intend to have offices in Australia and in Europe.